Modular Flatbed Cutters for Rigid, Roll, Textile, and Specialty Materials

Flatbed Tools is your US distributor for Summa’s F Series flatbed cutters — advanced engineered machines built for precision, flexibility, and scalability. Backed by over 30 years of expertise, the F Series allows professionals to cut various rigid boards, sheet materials, and roll stock with ease.

These future-proof cutting systems support a wide range of tooling, media handling, and automation options, opening the door to new markets including signage, packaging, point-of-sale, textiles, and industrial applications.

F1612 - Compact Powerhouse

The F1612 is Summa’s most compact flatbed cutter, perfect for sign makers who want to automate their cutting workflow or expand into new applications. Despite its small footprint, it delivers full modular tooling capabilities and seamless media handling.

Working Area: 63″ × 47″

Ideal for cutting: Cardboard, roll stock, textiles, synthetic materials, foamboard, wood

Key Benefits:

- Small footprint

- Easy installation

- Integrated Safety System

- Future-proof modular platform

1625 - Mid-Length, High Flexibility

The Summa F1625 offers a smart, scalable solution for production environments that need more cutting space than the F1612 - without jumping to a full wide-format footprint. With a 63″ × 98″ bed, it handles longer rigid boards, roll materials, and technical textiles with ease.

What sets the F1625 apart is its automation-driven workflow: Summa’s GoProduce™ software streamlines setup, tool settings, and job navigation, while features like automatic tool recognition and calibration ensure pinpoint precision with minimal operator intervention.

Its split-zone design allows simultaneous loading/unloading and cutting, making it a favorite for shops that value speed, reliability, and labor efficiency.

Working Area: 63″ × 98″

Applications: Signage, display, roll-fed media, packaging, textiles, synthetics, foamboard

Key Highlights:

- Operator Zone – Split the bed into an active cut zone and a loading/unloading zone for better control

- Tandem Workflow – Load or unload one side while cutting continues on the other

- Automatic Tool Recognition – Detects installed tools and loads pre-set parameters

- Automatic Device Calibration – Maintains peak accuracy across jobs and tool changes

- GoProduce™ Software – Automates material recognition, tool settings, and guided workflows

- Triple-head capacity and modular tool system

F1432 - Slim, Wide-Format Ready

The F1432 bridges the gap between the F1612 and F1832, processing popular 54″ roll widths with ease. Its longer bed makes it ideal for cutting 10 ft jobs, offering a smart upgrade path for growing production needs.

Working Area: 55″ × 126″

Ideal for cutting: Roll stock, lengthy materials, cardboard, textiles, synthetics

Key Benefits:

- Perfect interim size

- Modular tooling system

- Integrated Safety System

- Future-proof engineering

F1832 - Versatile Workhorse

The F1832 is a perfect match for 150 cm rolls and 5’ × 10’ rigid board materials. Add the High Torque rotary tool and you can confidently finish a wide range of textile applications too — all with Summa’s legendary precision.

Working Area: 71″ × 126″

Ideal for cutting: Cardboard, roll stock, textiles, synthetics, foamboard, wood

Key Benefits:

- Popular format compatibility

- Modular tooling system

- Integrated Safety System

- Textile-capable with rotary tool

F3220 - Built for 3.2M Production

Designed to perfectly align with 3.2 meter wide textile printers, the F3220 brings high-throughput and accuracy to large-format production. A seamless solution for print-and-cut workflows in the textile and display graphics industries.

Working Area: 128″ × 79″

Ideal for cutting: Flags, mesh, banners, textiles, 3m × 2m rigid board materials

Key Benefits:

- Matches 3.2 m printer output

- Heavy-duty roll support (HD RS)

- Integrated Safety System

- Future-proof modular platform

F3232 - Maximum Cutting Surface

Working Area: 128″ × 126″

The largest F Series cutter available. Designed for oversized production environments, high-volume workflows, and maximum throughput.

Use case: Oversized rigid sheets, industrial fabrication, textile and foam cutting.

Supported Tools & Materials

All F Series models support Summa’s interchangeable tooling modules for cutting, creasing, routing, and perforating.

Available tools include:

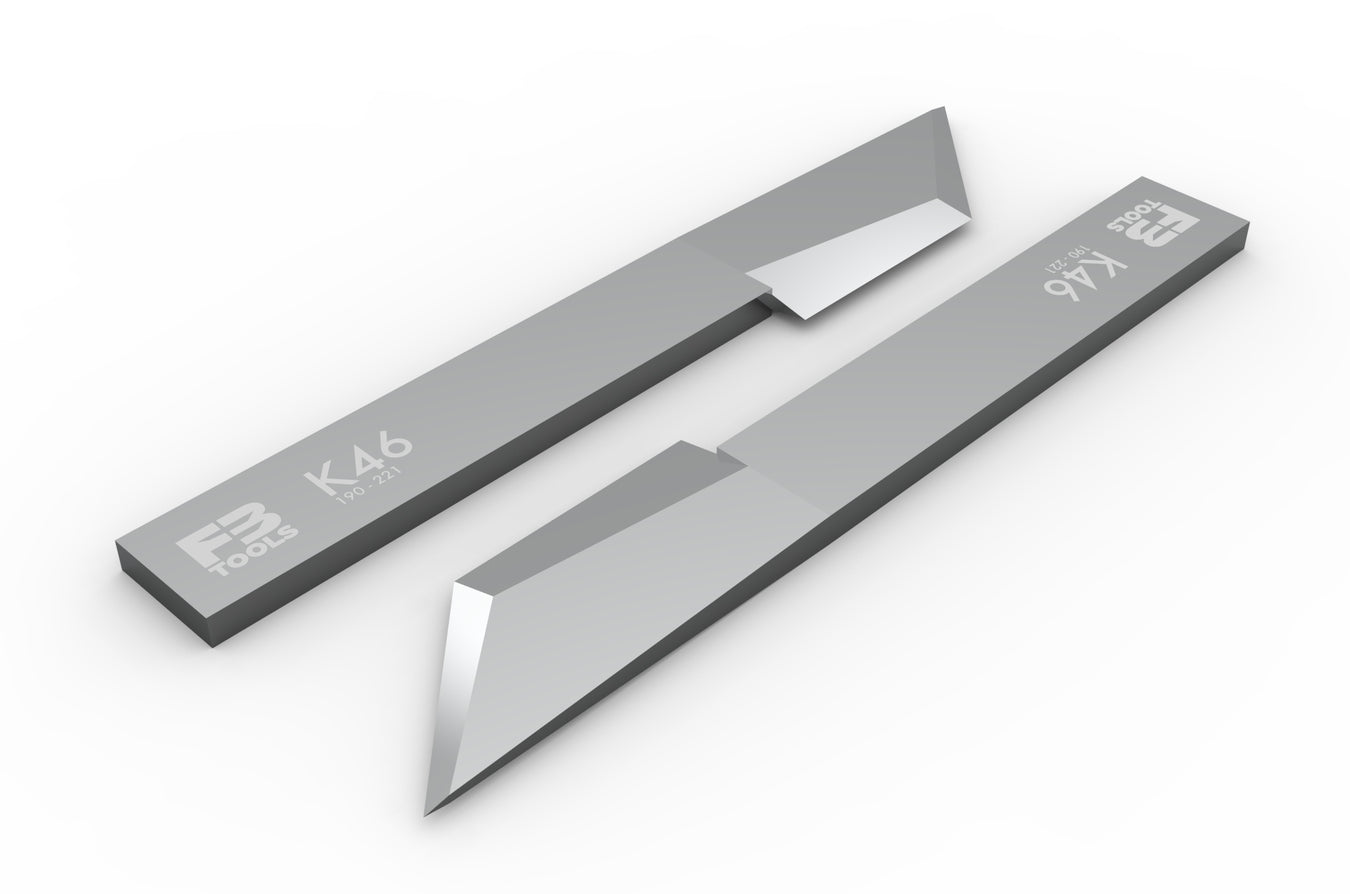

- Drag knives

- Kiss-cut tools

- Oscillating knives

- V-cut tools

- Creasing wheels

- Routing modules

Ideal for processing:

- Foam board

- Corrugated plastic

- PVC and rigid sheets

- Textiles and technical fabrics

- Cardboard and packaging materials

- Magnetic and synthetic media

- Wood and soft composites (F1832+)

Let’s Build Your Flatbed Cutting Workflow

Flatbed Tools provides quote-only sales for Summa equipment, allowing us to match the best machine, tool set, and configuration to your specific workflow.

Whether you’re cutting signage, fabric, packaging prototypes, or custom materials, we’re here to help.